Brake Pad Range

EBC’s entirely UK-made pad range is quite possibly the largest on the planet; covering over 10,000 vehicles from the 1950s to the present, with several innovative friction materials to choose from.

Whether you’re seeking an OE quality pad for your daily driver, a performance pad for spirited road driving, a heavy-duty pad for your 4x4, or a motorsport pad for your racing car, FitEBC has the optimal pad upgrade for your own unique application shipped from stock held here on Australian soil.

Explore the EBC pad range:

In a rush? View our brake pad material quick guide here

Know the typical operating temperatures of your brake system during spirited driving? If so, use this guide for easy comparison between the operating temperature ranges for every EBC friction material.

SAVE 15% when buying pads and discs in the same cart.

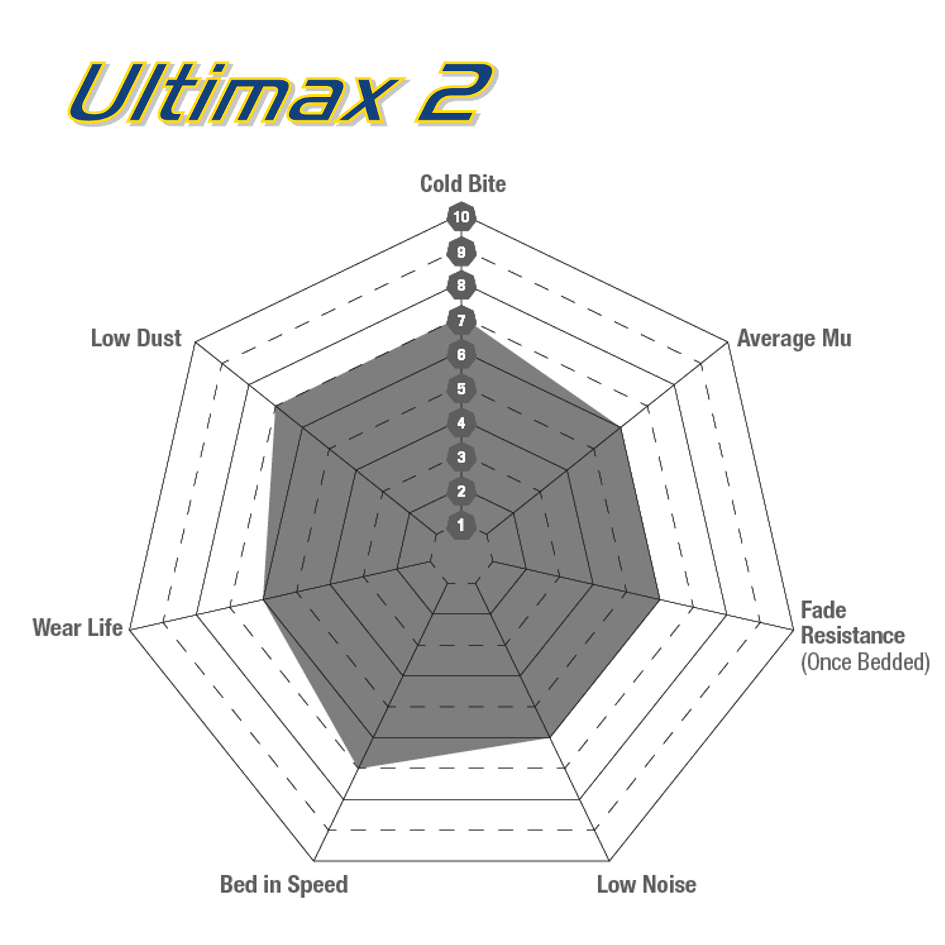

Ultimax

BEST FOR

- A direct equivalent to OEM brake pads

- Excellent value for general daily driving

- Good cold friction and silent operation

EBC Ultimax is a premium replacement pad with equivalent performance to the OE brake pads your vehicle came fitted with from the factory. Despite matching the performance and quality of OE pads, Ultimax represents a massive saving over original equipment parts, often costing half the price or less. Ultimax is ideally suited for daily driving of modestly powered cars that are not routinely driven hard.

Despite being EBC’s entry-level pad range, Ultimax is made in the same British factory as all EBC brake pads and therefore doesn’t compromise on quality despite the keen price point. The entire Ultimax range is tested and approved to ECE R90 safety regulations, meaning Ultimax is ADR compliant and thus fully legal for use on public roads in Australia.

Ultimax possesses strong friction from cold, offers totally silent braking and typically produces less dust than many original or aftermarket brake pads. EBC Ultimax has also been awarded the highest ‘N’ rating by the U.S. Environmental Protection Agency, meaning this brake material contains zero heavy metals, zero asbestos and zero copper, making it one of the most environmentally friendly brake materials on the market.

NOTE: This material is not suitable for hard driving or any kind of track use.

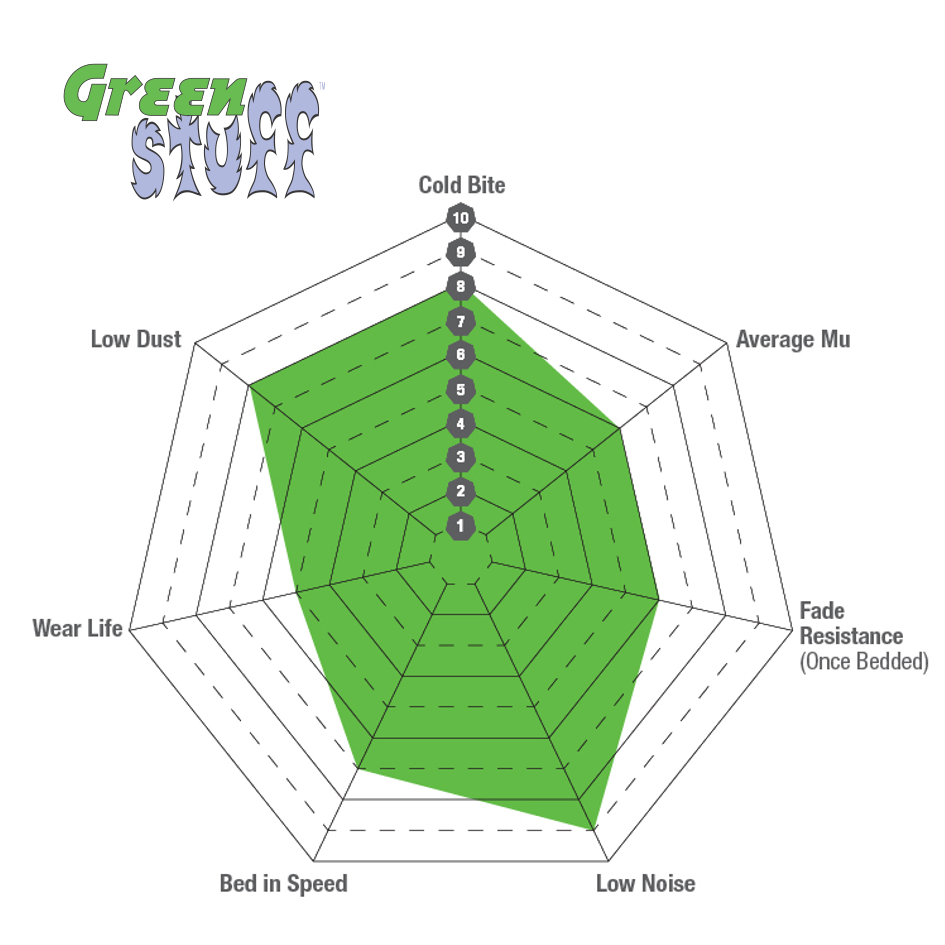

GreenStuff

BEST FOR

- Entry-level upgrade for sport road driving

- 15% higher bite than OEM brake pads

- Modest improvement to fade resistance vs. OEM

EBC GreenStuff is an entry-level pad upgrade suitable for modestly powered cars & SUVs driven spiritedly on the public roads, but that are never driven on track. GreenStuff boasts 15% higher friction than OEM brake pads, giving a noticeable increase in braking power which helps shorten stopping distances. GreenStuff is also a popular choice for classic cars, where the 15% higher friction level brings improved stopping power (especially beneficial for classic cars without servo assistance).

GreenStuff offers a modest improvement in fade resistance over OEM brake pads and boasts an excellent pedal feel. GreenStuff also has a very low metallic content which minimises brake rotor wear.

GreenStuff is manufactured in EBC’s factory in Great Britain and is approved to ECE R90 standards, meaning GreenStuff is ADR compliant and thus fully legal for use on public roads in Australia.

EBC GreenStuff has also received the highest ‘N’ rating by the U.S. EPA for its environmental credentials, meaning this brake material contains zero heavy metals, zero asbestos and zero copper, putting it among some of the most environmentally friendly brake materials on the planet.

NOTE: This material is not suitable for spirited driving in high-powered vehicles or for any kind of track use.

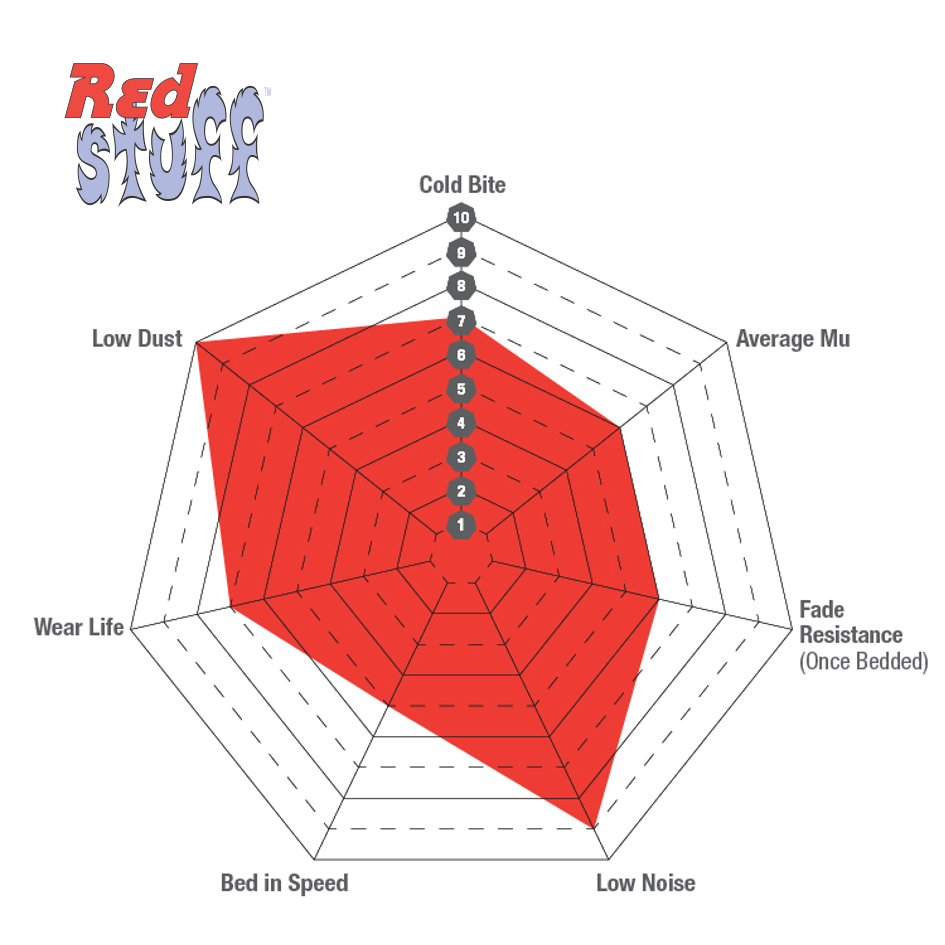

RedStuff

BEST FOR

- Extremely low brake dust

- 15% higher bite than OEM brake pads

- Significant improvement in fade resistance vs. OEM

EBC RedStuff can be summarised in two words: low dust. RedStuff is made from an advanced ceramic* friction compound which minimises brake rotor wear and ensures this pad produces extremely low levels of brake dust, helping to keep wheel rims cleaner for longer.

RedStuff provides a 15% higher friction level and improved fade resistance compared to OEM brake pads, making it well suited for semi-spirited road driving as well as general ‘daily driver’ use on prestige vehicles looking to keep brake dust to an absolute minimum.

RedStuff is produced in EBC’s factory in Bristol, UK, and is approved to ECE R90 making it fully ADR compliant and totally legal for use on public roads in Australia. RedStuff has also received the top ‘N’ rating from the U.S. Environmental Protection Agency, meaning this brake material contains zero harmful materials and that brake wear emissions have an extremely low impact on the environment and marine life.

NOTE: RedStuff is not suitable for any kind of track use.

* Ceramic pad content, not to be confused as being suitable for use on carbon ceramic rotors. RedStuff is suitable for use on cast-iron rotors only.

TIP: Frequently customers end up with a toss-up between EBC RedStuff and YellowStuff compounds. Our recommendation would be to choose YellowStuff for higher overall braking performance and for a longer pad life, or if low dust is the primary aim, choose RedStuff. Another important factor is RedStuff is not suitable for any kind of track use, whereas YellowStuff is suitable for the occasional trackday. If you drive your vehicle spiritedly on the road or plan on doing a trackday, YellowStuff will inspire greater confidence, be more fade-resistant and wear much slower than RedStuff at these higher duty levels.

YellowStuff

BEST FOR

- Flagship fast road and light track material

- Progressive braking with excellent pedal feel

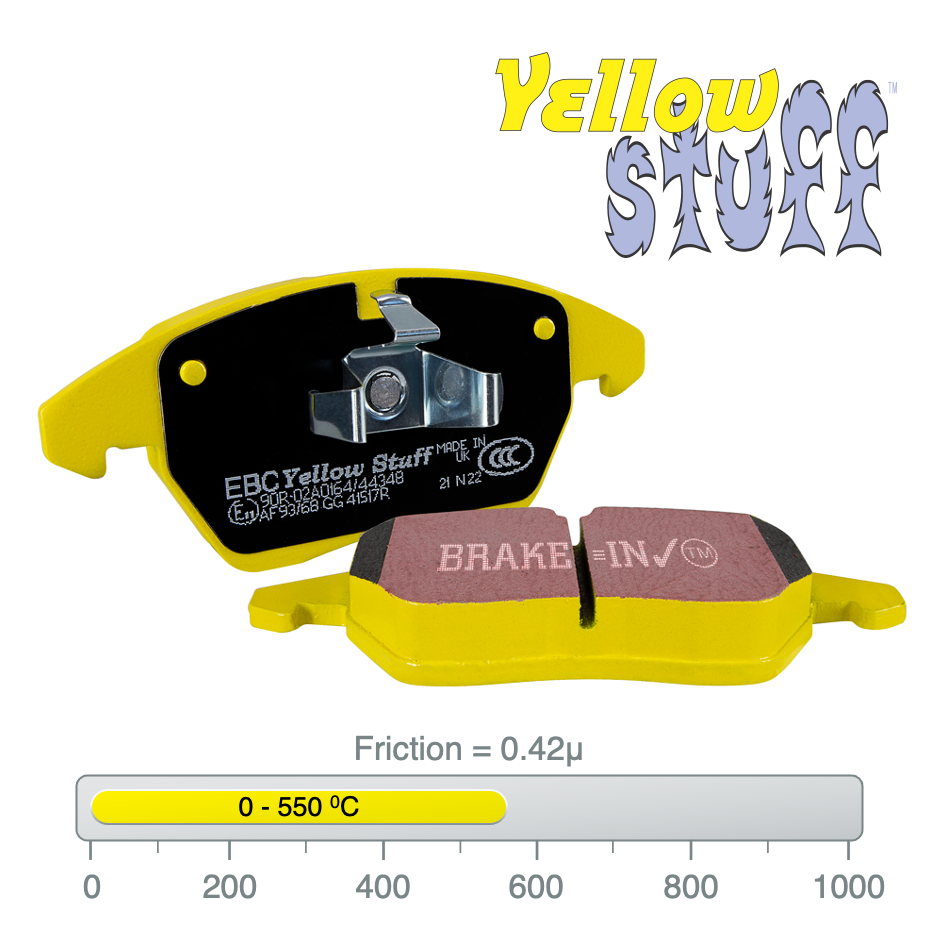

- Friction = 0.42, Temp range = 0 – 550°C

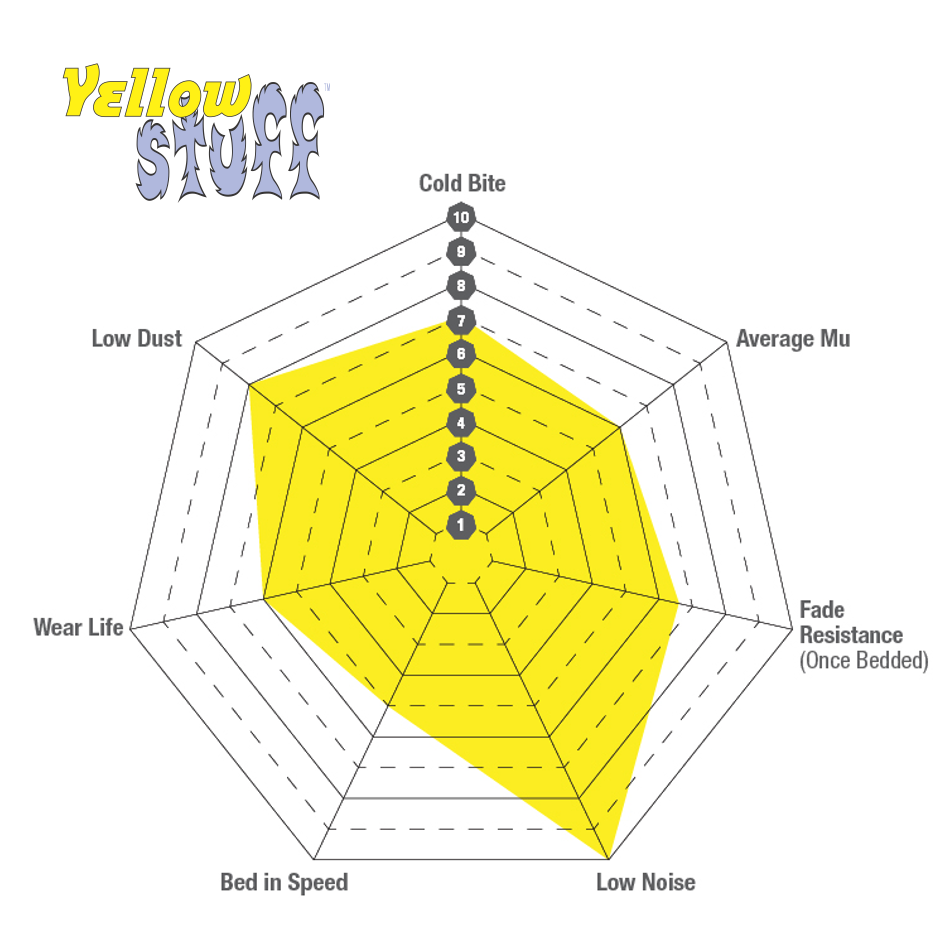

YellowStuff is EBC’s top-selling, flagship material for performance road driving and it’s easy to see why. YellowStuff strikes the optimum balance between outright performance and day-to-day usability, making it an ideal choice for performance vehicles driven enthusiastically on the public road or that do the occasional track day. YellowStuff is also a popular upgrade for trucks, 4x4s and SUVs where the significantly boosted stopping power helps shorten braking distances, especially with heavily laden vehicles or when towing big loads.

The material is approved to ECE R90 meaning YellowStuff is ADR compliant and thus totally legal for use on public roads in Australia. YellowStuff has a stable friction coefficient of 0.42 over a broad temperature working range of 0 - 550°C

YellowStuff has superb road manners, producing less brake dust than most OE brake pads whilst also being silent in operation. The material also boasts excellent pedal modulation and good wear life, even when pushed hard on the road or track.

YellowStuff is manufactured in Bristol, United Kingdom. Unlike many other high-performance brake pads on the market, YellowStuff has been awarded the top ‘N’ rating by the U.S. EPA for its environmental credentials, meaning YellowStuff contains zero copper or other harmful materials that research shows can contaminate waterways and pose a threat to marine life.

NOTE: YellowStuff also makes a great race compound on lighter/modestly powered vehicles, however for heavier/high-power vehicles frequently driven very hard on the road or regularly doing trackdays, consider BlueStuff which is still 100% road legal but is more biased towards improved on-track performance. The additional benefit of BlueStuff is that the bedding-in time is roughly 3x shorter than YellowStuff, perfect for customers who want a more ‘plug n play’ brake pad.

BlueStuff

BEST FOR

- Highest-performing road-legal material

- 20% longer life than YellowStuff

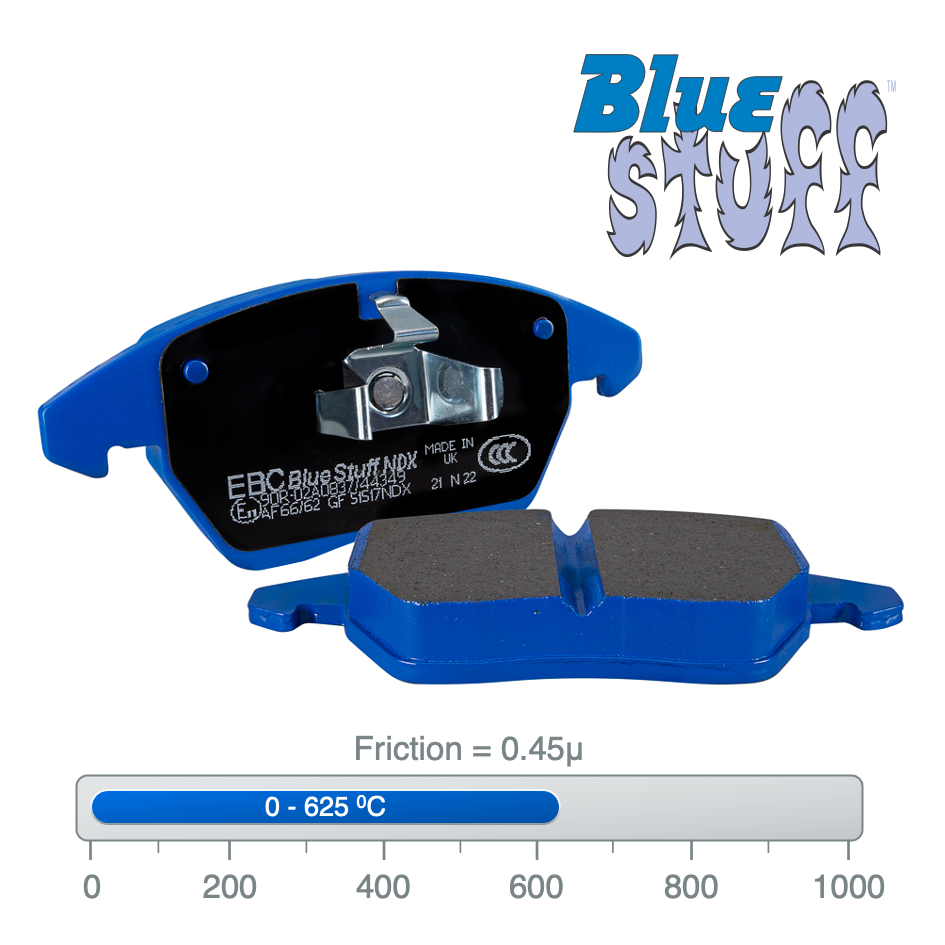

- Friction = 0.45, Temp range = 0 – 625°C

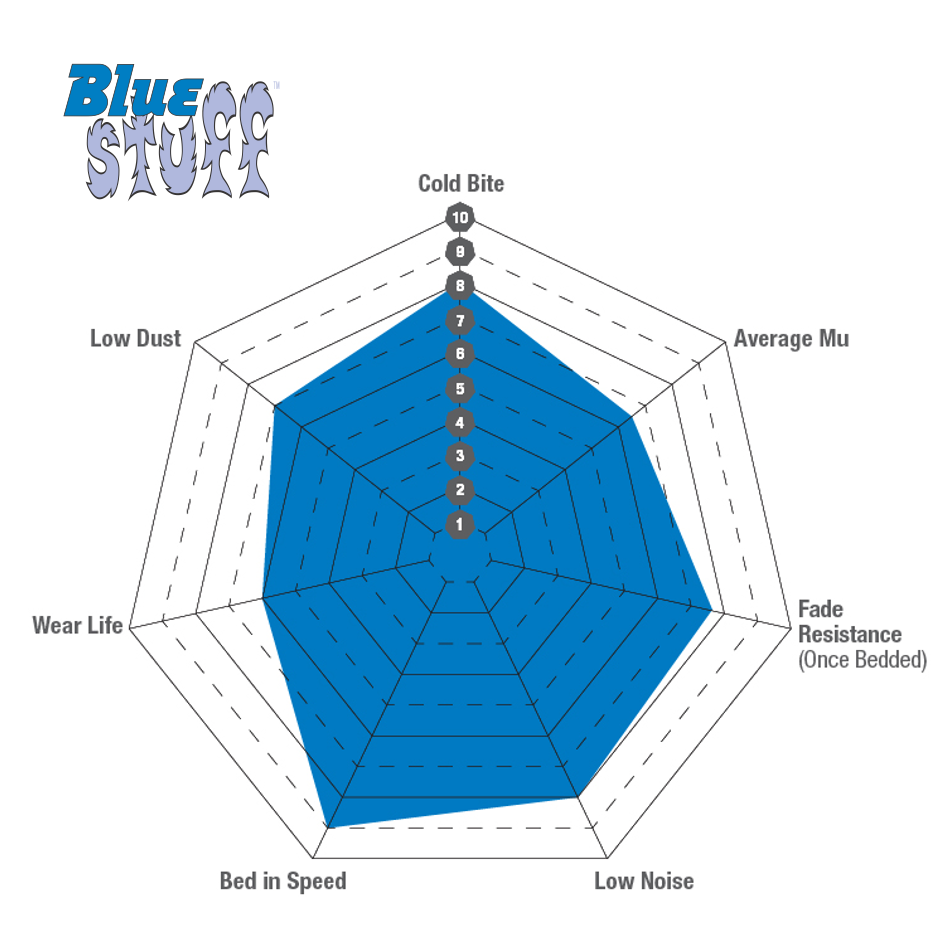

BlueStuff is EBC’s highest performing ECE R90-approved material, meaning BlueStuff complies with ADRs and is therefore fully legal for use on the public roads in Australia. BlueStuff’s high performance and road legality make it the brake pad of choice for many trackday enthusiasts who wish to drive to/from the circuit, as well as club racers looking for a cost-effective motorsport pad.

Where YellowStuff is fundamentally a road pad that can also handle occasional track use, BlueStuff is a track-focussed brake pad that has been dialled down to comply with ECE R90 and possess reasonable road manors. The result is that BlueStuff has a slightly higher friction coefficient of 0.45 and a wider temperature working range of 0 – 625°C. BlueStuff also has a 3x shorter bedding-in time compared to YellowStuff, making it more of a ‘plug n play’ brake pad.

The trade-off for BlueStuff’s higher fade resistance and longer wear life (vs. YellowStuff) can result in some light brake noise and increased brake dust (however in most instances brake noise is minimal since these pads are still supplied fitted with OEM-style anti-noise shims).

If you’re looking to extract the maximum performance from your vehicle’s brake system, whilst still using a road-legal pad that is fully ADR compliant and has acceptable road manors, BlueStuff is an excellent choice.

BlueStuff is manufactured in EBC’s factory in Bristol, UK. Despite its high performance, BlueStuff still achieves the highest ‘N’ rating from the U.S. Environmental Protection Agency, meaning it contains no harmful materials and any brake wear emissions pose a very low risk to the environment and marine life.

NOTE: The huge stopping power and high fade-resistance of BlueStuff also make this material a popular choice for trucks, SUVs and 4x4s doing serious off-roading or towing big loads.

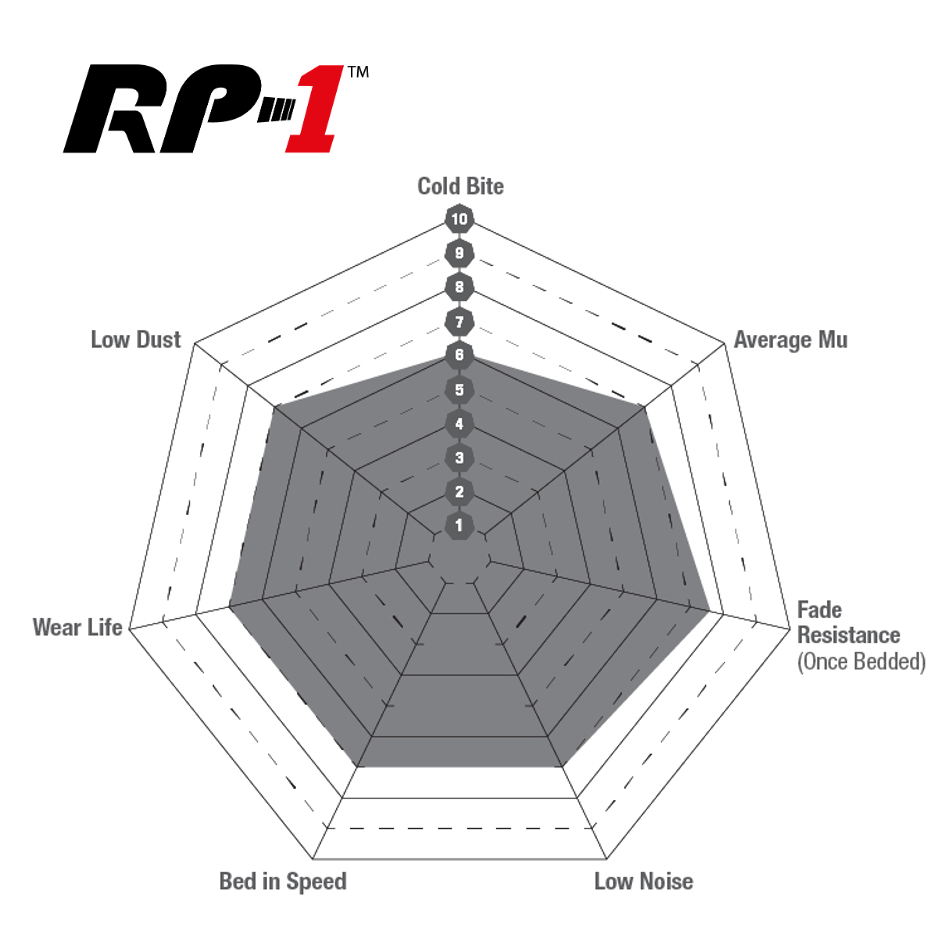

RP-1

BEST FOR

- 0.45 mu pad for sprint race and trackday use

- Maximum control and pedal feel

- Extremely low brake rotor wear

RP-1 is a sprint race material from EBC’s motorsport division, EBC Brakes Racing. RP-1 possesses a stable friction coefficient of 0.45 from 100 - 750°C, making it suitable for heavy track use in thermally demanding applications. Below 100°C RP-1 has a usable yet slightly diminished friction level of 0.35, however, friction gently climbs to its nominal friction level of 0.45 after a couple of medium energy snubs and then stays there (i.e. it is possible to drive RP-1 from ‘cold’ however it takes a couple braking events before full brake effect is realised).

RP-1 has a progressive pedal feel with the best modulation of any material in the EBC range, allowing the driver to precisely meter out their braking inputs and trail brake with finesse.

RP-1 boasts good pad life; however, its standout characteristic is exceptionally low rotor wear. This is principally due to RP-1, unlike most other race compounds on the market, having a very low metal-fibre content. RP-1 achieves its high level of performance through adhesive friction, rather than by simply being abrasive like a scouring pad. Not only does this drastically reduce rotor wear but it also means any brake dust produced has minimal metallic content, preventing metallic ‘hot rocks’ from becoming embedded and damaging expensive alloy wheels, as is common with many other track pads. Any wheel dusting produced by RP-1 is easily washed off.

It should however be noted that, due to RP-1 being a motorsport product developed solely for track use, RP-1 is not ECE R90 homologated for road use and is therefore not legal for use on public roads in Australia.

Compared to EBC Racing’s other sprint race material RP-X, RP-1 has a 20% lower friction coefficient across its working temperature range which makes RP-1 better suited to cars where the brake system is inherently over-servoed from the factory. For cars with a ‘sharp’ brake pedal response, the less aggressive bite of RP-1 can help to promote control (for example, RP-1 works well on many Porsches, BMW M cars, performance VAG vehicles etc.). If you’re unsure whether RP-1 or RP-X is likely to be better suited to your vehicle or driving style, please speak to a member of our technical team who will be delighted to guide you based on our considerable experience with EBC Racing’s materials.

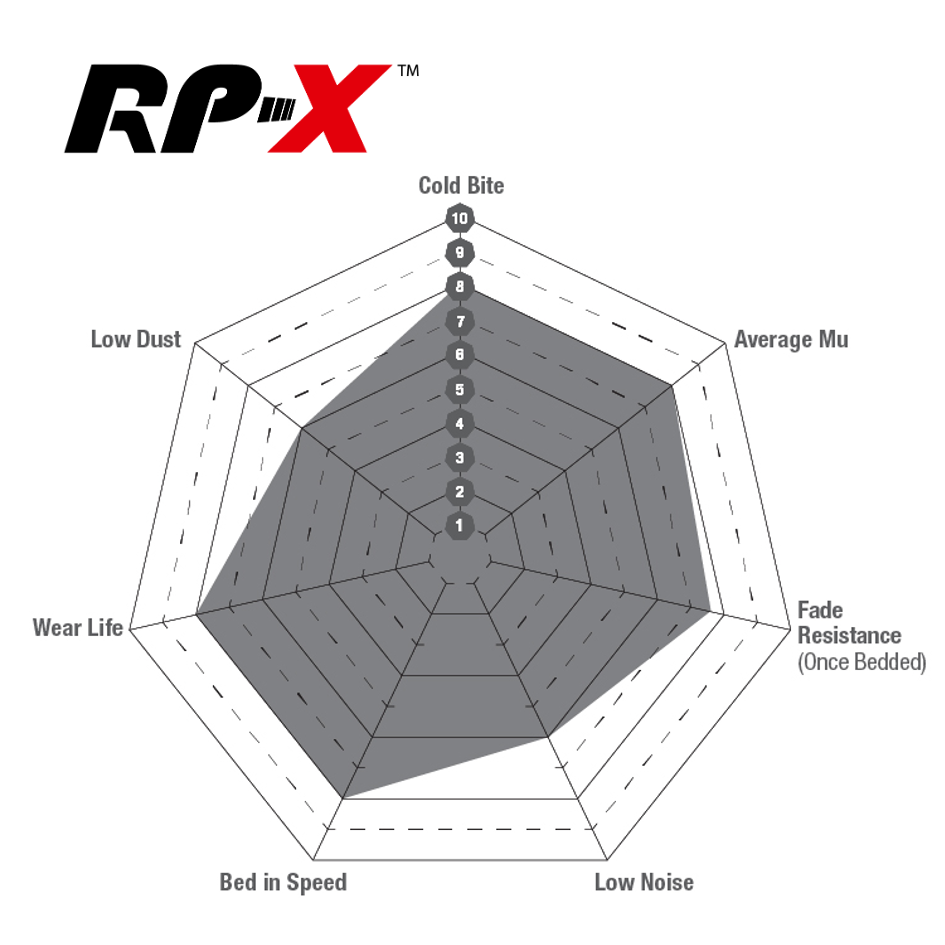

RP-X

BEST FOR

- 0.55 mu pad for sprint race and trackday use

- Wide operating temp range of 0 – 750°C

- High-torque, full brake effect from cold

RP-X is a high-torque material designed for sprint race and trackday use. RP-X possesses a friction coefficient of 0.55 and is stable from 0 – 750°C making it an excellent compound for thermally demanding motorsport applications. The fact RP-X achieves full brake effect from cold means RP-X is a popular choice for Time Attack, Rallycross and Hillclimb events, where no warm-up is possible, meaning drivers require 100% brake effect from the first pedal application.

RP-X is developed solely for use in motorsport and is not ECE R90 approved, making it illegal to use RP-X on public roads in Australia. Furthermore, although RP-X meets the standard for obtaining the highest ‘N’ for its environmental credentials, as it contains zero copper, zero asbestos and zero heavy metals, given RP-X’s motorsport focus this material has not been formally tested according to this US environmental regulation.

RP-X gives 20-30% longer pad life than RP-1, especially when run at higher temperatures, however, the high-torque nature of RP-X means it is much more aggressive on brake rotors (but no worse on rotors than many other race materials on the market). RP-X tends to work best on vehicles that have inherently under-servoed brakes, where RP-X’s more aggressive bite helps to supplement braking power without being overwhelming (in this regard, RP-X works well on Japanese and Korean manufactured vehicles, which typically have lower brake assistance than performance cars originating from Europe and elsewhere).

If you’re unsure whether RP-1 or RP-X is likely to be better suited to your vehicle or driving style, please speak to a member of our technical team who’ll be delighted to guide you based on our considerable experience using both materials.

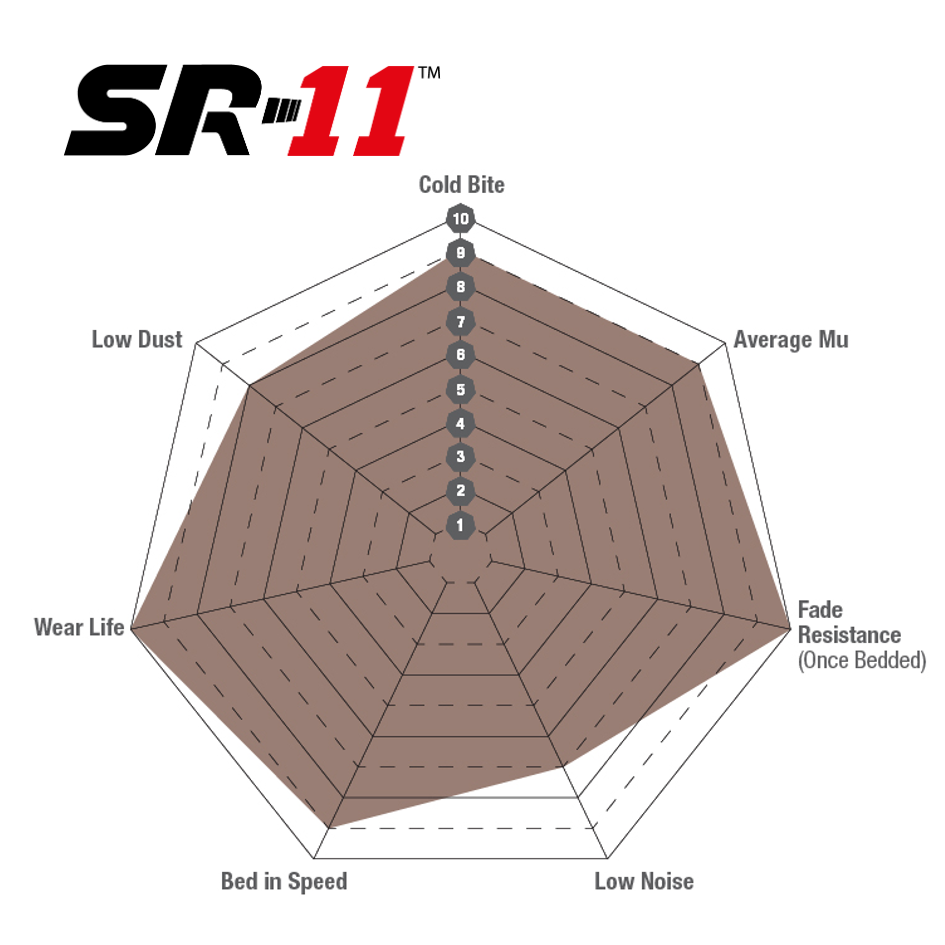

SR-11

BEST FOR

- Sintered endurance race compound

- Medium-torque, friction = 0.50 mu

- Extremely low pad & rotor wear

SR-11 is a state-of-the-art endurance race compound from EBC Racing that employs sintered friction technology to take cast-iron brake performance to the next level. SR-11 has an ultra-wide temperature working range of 0 – 925°C with a near perfectly flat friction profile of 0.5 mu throughout. SR-11 is a medium-torque material targeted at applications where a more progressive brake response is desirable, such as vehicles with servo-assistance, non-aero racing cars or rear axle fitment.

SR-11 boasts exceptionally low pad wear, yet unlike some other sintered brake pads on the market, the remarkable reality is that SR-11 also exhibits virtually zero brake rotor wear. SR-11 has been developed and independently tested for use in LM GTE class motorsport and has such low wear it could feasibly complete the 24hrs of Le Mans without a single pad or rotor change. As such, SR-11 is marketed as an endurance grade product, however, SR-11’s very stable performance from cold makes it highly suitable for use in any type of motorsport where cars run a cast-iron brake rotor, including sprint race, circuit racing, Time Attack, rallying, Hillclimb and serious trackday use.

Whilst SR-11’s high initial cost requires a significant up-front investment, the cost-per-racing-mile of EBC’s sintered pads is considerably lower than virtually any other brake pad on sale today, thanks to SR-11’s extraordinary pad and rotor life. Furthermore, whereas many semi-metallic or organic race pads ‘dull off’ after their first heat cycle, SR-11 experiences zero degradation between sessions meaning the same set of pads can provide between 20-60 hours of consistent performance at full racing speed. It’s not uncommon for 1 set of SR-11 brake pads to last an entire racing season, with zero drop-off in performance from the day they’re installed till they’re worn right down to the backplate.

Being a sintered metal pad SR-11 also possesses ultra-low compressibility, resulting in a very firm pedal with an unrivalled pedal feel. This gives the driver absolute control during each and every braking zone, with even the slightest change in pedal force instantly translating to a proportionate change in torque output.

Despite SR-11 being developed for use at the highest levels of motorsport, somewhat surprisingly SR-11 also has good street manors, with full brake effect from cold and many drivers reporting little-to-no noise with minimal brake dust. This is in stark contrast to most other race pads which squeal loudly at any speed and pedal pressure. Unfortunately, however, due to SR-11’s focus on motorsport use, this material has not been tested to ECE R90 standards and therefore is not legal for use on public roads in Australia (although customers in non-R90 regulated markets could conceivably run SR-11 on the road with excellent results).

Another benefit to SR-11, and a characteristic common to all sintered friction materials, is it has effectively no bedding-in period; requiring only a couple of laps at 80% racing speed to ensure the pads are mated up to the brake rotor. This is because sintered friction materials contain no volatiles that could burn, de-gas and lead to ‘green fade’, making SR-11 a true ‘plug n play’ motorsport pad.

SR-11’s extreme fade resistance, unrivalled pedal modulation and huge wear life mean EBC Racing’s sintered endurance race pads really are the Holy Grail for motorsport teams and drivers seeking the pinnacle of braking performance. Quite simply, EBC Racing’s new sintered pad materials are achieving levels of performance previously thought to be impossible on a cast-iron brake rotor.

Want to learn more about sintered pad technology, we’ve written a great blog on this topic which you can read here

NOTE: SR-11’s sister material, SR-21, has a higher friction coefficient of 0.6 for applications where high torque output is desirable, such as vehicles without any servo-assistance, high aero loads or front axle fitment.

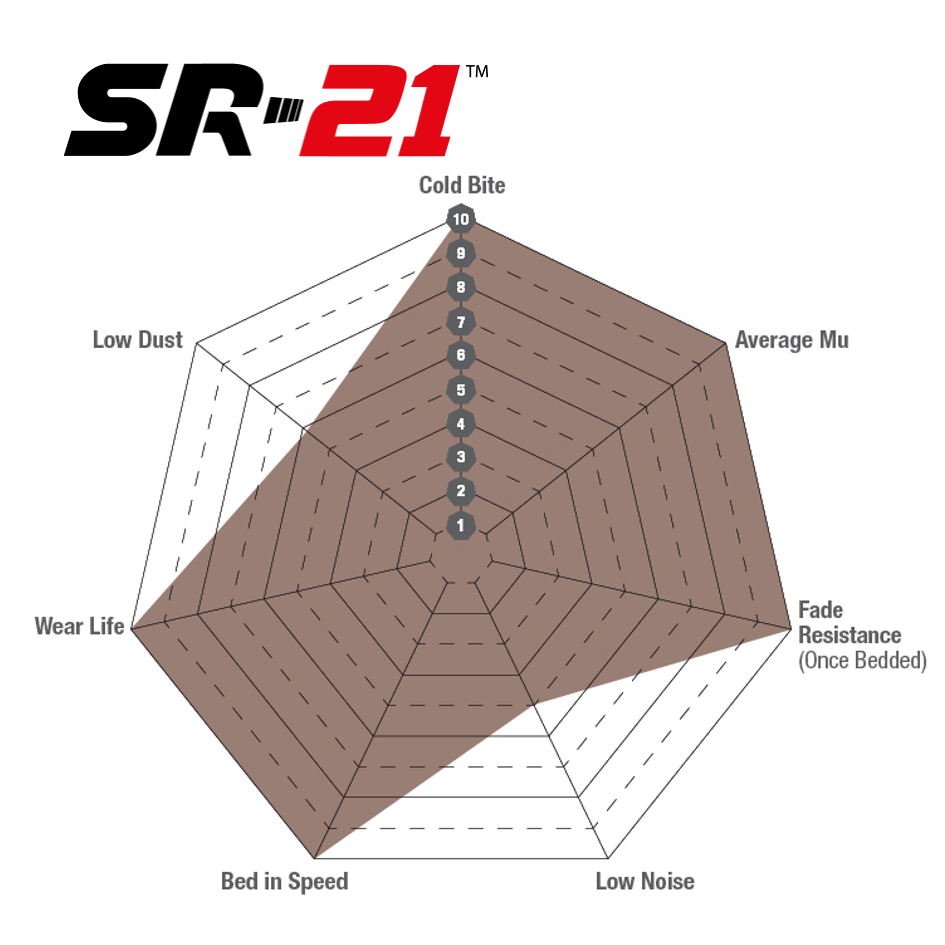

SR-21

BEST FOR

- Sintered endurance race compound

- High torque, friction = 0.60 mu

- Extremely low pad & rotor wear

SR-21 is the sister compound to SR-11 that employs state-of-the-art sintered friction technology to take cast-iron brake performance to the next level. SR-21 has the widest temperature working range of any material in the EBC range of 0 – 950°C, with a near perfectly flat friction profile of 0.6 mu across its entire operating range. SR-21 is a high-torque material targeted at applications where a high initial bite is desirable, such as vehicles with minimal servo-assistance, racing cars generating significant aero loads or front axle fitments.

SR-21 boasts exceptionally low pad wear, yet unlike some other sintered brake pads on the market, SR-21 also exhibits virtually zero brake rotor wear. SR-21 has been developed and independently tested for use in LM GTE class motorsport and has such low wear it could feasibly complete the 24hrs of Le Mans without a single pad or rotor change. As such, SR-21 is marketed as an endurance grade product, however, SR-21’s very stable performance from cold makes it highly suitable for use in any type of motorsport where cars run a cast-iron brake rotor, including sprint race, circuit racing, Time Attack, rallying, Hillclimb and serious trackday use.

Whilst SR-21’s high initial cost requires a significant up-front investment, the cost-per-racing-mile of EBC’s sintered pads is considerably lower than virtually any other brake pad on sale today, thanks to SR-21’s extraordinary pad and rotor life. Furthermore, whereas many semi-metallic or organic race pads ‘dull off’ after their first heat cycle, SR-21 experiences zero degradation between sessions meaning the same set of pads can provide between 20-60 hours of consistent performance at full racing speed. It is not uncommon for 1 set of SR-21 brake pads to last an entire racing season, with zero drop-off in performance.

Being a sintered metal pad SR-21 also possesses ultra-low compressibility, resulting in a firm pedal with an unrivalled pedal feel. This gives the driver absolute control during each and every braking zone, with even the slightest change in pedal force instantly translating to a proportionate change in torque output.

Despite SR-21 being developed for use at the highest levels of motorsport, SR-21 has reasonable road manors, with full brake effect from cold and less brake noise than typical semi-metallic race pads (although SR-21 is typically noisier than its sister material SR-11). Due to SR-21’s focus purely on motorsport use, this material has not been tested to ECE R90 standards and therefore is not legal for use on public roads in Australia.

Another benefit to SR-21, and a characteristic common to all sintered friction materials, is it has effectively no bedding-in period; requiring only a couple of laps at 80% racing speed to ensure the pads are mated up to the brake rotor. Sintered pads contain no volatiles that could burn, de-gas and lead to ‘green fade’, making SR-21 the ultimate ‘plug n play’ motorsport pad.

SR-21’s extreme fade resistance and huge wear life mean EBC Racing’s sintered endurance race pads really are the Holy Grail for motorsport teams and drivers seeking the pinnacle of braking performance. Quite simply, EBC Racing’s new sintered pad materials are achieving levels of performance previously thought to be impossible on a cast-iron brake rotor.

Want to learn more about sintered pad technology, we’ve written a great blog on this topic which you can read here

NOTE: SR-21’s sister material, SR-11, has a lower friction coefficient of 0.5 for applications where a more benign brake response is desirable, such as vehicles with increased servo-assistance, non-aero racing cars or rear axle fitment. SR-11 has better road manners than SR-21, typically exhibiting less noise and lower brake dust.

Validate your login